Completed Research

BENEFITS PROJECTS

DEVELOPING METHODOLOGIES TO PREDICT AND QUANTIFY THE BENEFITS OF IRISE RESEARCH.

Abstract: This report provides the results of benefit analyses performed for five projects conducted by IRISE:

Abstract: This report provides the results of benefit analyses performed for five projects conducted by IRISE:

- Early Opening of Concrete Pavements to Traffic

- Preliminary Evaluation of Pavement Surface Distresses Related to Pavement Markings

- Remote-Controlled Technology Assessment for Safer Pavement Construction and QA/QC

- Development of a Simplified Mechanistic-Empirical Design Tool for Pennsylvania Rigid Pavements

- Material Compatible Repairs (MCRs) for Concrete Pavements and Bridge Decks

Each of the projects was examined in detail to determine the types of unique benefits that may be expected and then quantified based upon direct and indirect impacts. Current analysis methodologies were researched and evaluated and novel methods or new practices were developed to predict improvements in highway infrastructure longevity achievable by applying the innovations suggested by the research. Potential cost reductions were also assessed based on cost data obtained from PennDOT . Based upon case studies performed on an individual project basis, the potential benefits and cost reductions were determined to be significant.

Dr. Mark Magalotti, PE: mjm25@pitt.edu

One Page Summaries:

BRIDGE PROJECTS

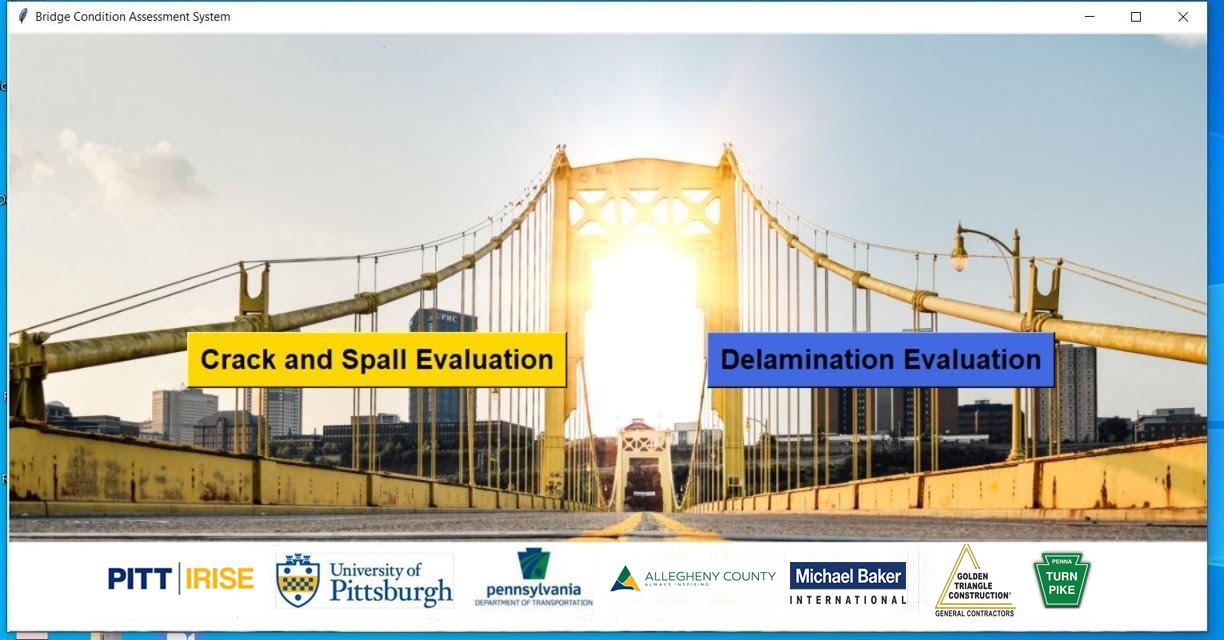

IMPROVING BRIDGE ASSESSMENT THROUGH THE INTEGRATION OF CONVENTIONAL VISUAL INSPECTION, NON-DESTRUCTIVE EVALUATION, AND STRUCTURAL HEALTH MONITORING DATA

Abstract:The purpose of this study was to establish a framework capable of integrating traditional non-destructive evaluation (NDE) and emerging automated unmanned aerial vehicle (UAV)-based techniques to provide improved performance assessment of bridges. The framework focuses on addressing the principal challenges associated with studying the service life of bridge structures: (a) the long time scales (which requires accelerated aging), (b) the diverse outputs related to bridge condition (in terms of data collected through UAV, NDE, and visual inspection), and (c) an advanced data interpretation and fusion framework for automated detection and quantification of bridge surface and subsurface defects.

Abstract:The purpose of this study was to establish a framework capable of integrating traditional non-destructive evaluation (NDE) and emerging automated unmanned aerial vehicle (UAV)-based techniques to provide improved performance assessment of bridges. The framework focuses on addressing the principal challenges associated with studying the service life of bridge structures: (a) the long time scales (which requires accelerated aging), (b) the diverse outputs related to bridge condition (in terms of data collected through UAV, NDE, and visual inspection), and (c) an advanced data interpretation and fusion framework for automated detection and quantification of bridge surface and subsurface defects.

By leveraging the access to the unique dataset generated by the Bridge Evaluation and Accelerated Structural Testing (BEAST) facility, this study aimed to identify the potential synergies among bridge degradation, remaining service life, and the results taken from the multimodal sensing technologies (i.e., UAV and NDE techniques). Data processing frameworks based on deep learning and a systematic UAV data collection strategy were developed to automatically detect the surface defects from HD images and subsurface defects from Infrared thermography (IR) images.

New multi-source NDE data fusion methods based on discrete wavelet transforms and improved Dempster-Shafer evidence combination theory were proposed to provide a more comprehensive concrete bridge deck assessment.

Dr. Amir Alavi: alavi@pitt.edu

STEEL BRIDGE CORROSION PREVENTION AND MITIGATION STRATEGIES

Abstract: Corrosion in steel bridges exposed to chloride attack from exposure to marine environments or de-icing salts is a significant issue which decreases structural integrity and increases maintenance requirements. Steel bridges exposed to these conditions require regular inspection, maintenance and rehabilitation, which drastically increases life-cycle costs.

This report provides a comprehensive literature review which highlights important issues related to corrosion in steel bridges with the objective of identifying shortcomings in current practice in Pennsylvania and identifying novel methods for further study and/or possible implementation. First, common forms of corrosion in steel infrastructure are reviewed. Next, corrosion prevention, mitigation and repair strategies are discussed including strategies currently utilized in Pennsylvania and by other state DOTs. Finally, promising corrosion prevention, mitigation and repair solutions are recommended. These solutions include: (1) implementing duplex coating systems, (2) identifying and evaluating novel approaches to prevent and mitigate crevice corrosion, (3) developing AI enabled corrosion monitoring methodologies, (4) eliminating joints in existing structures using debonded link slabs, and (5) further developing in-situ repair strategies for corrosion damaged components.

Dr. Jason Mash, PE: jam523@pitt.edu

GEOTECH PROJECTS

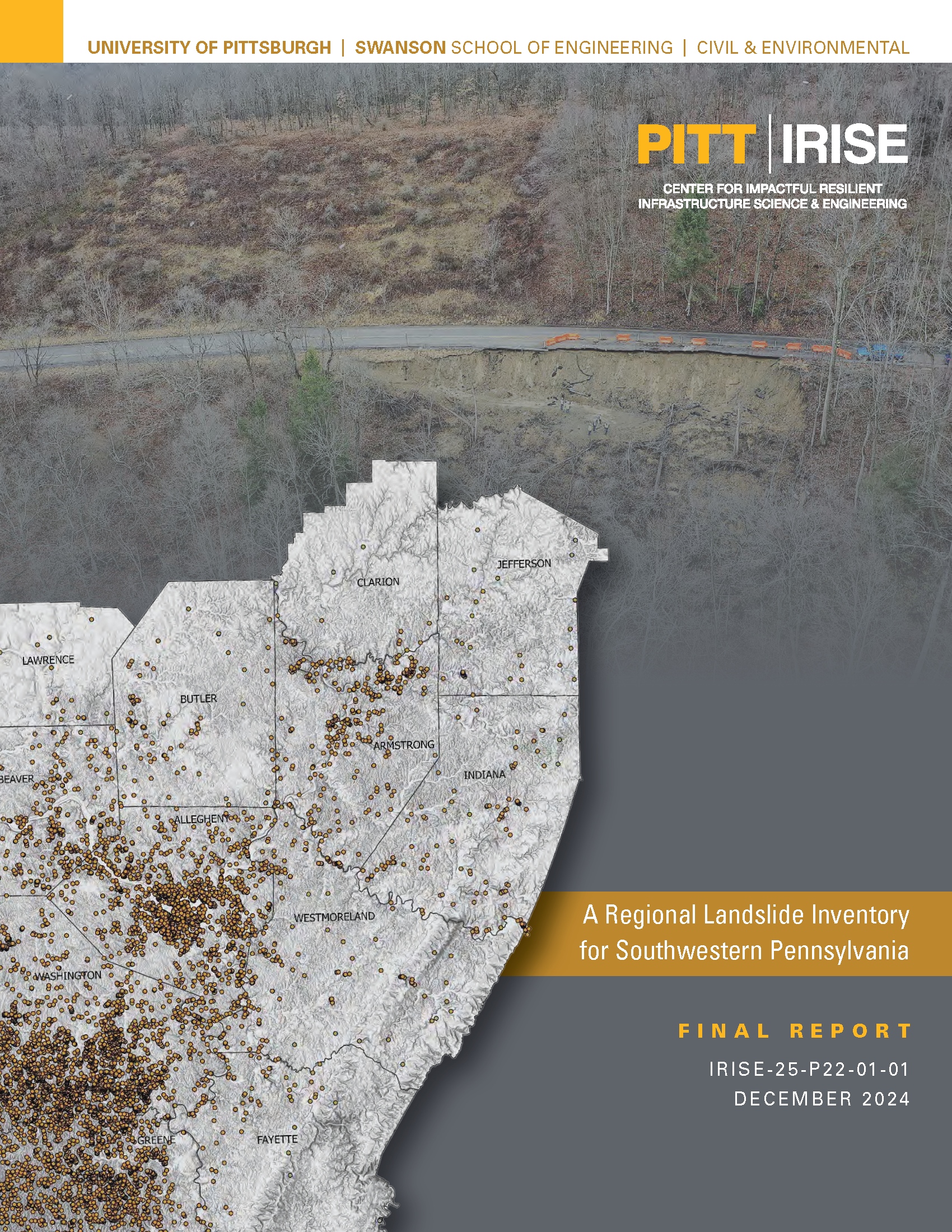

A Regional Landslide Inventory for Southwestern Pennsylvania

Abstract: Landslides are a major disruption to road networks and infrastructure in Southwestern Pennsylvania. A combination of rugged topography, clay-rich bedrock, complicated hydrogeology, and changing local climate results in numerous landslides across the region, particularly in areas where humans have modified the landscape. However, documentation of the spatial and temporal patterns of these landslides is spread across a wide range of government agencies and historical sources. This limits comprehensive planning efforts to address ongoing damage and mitigate potential future landslides. This project has inventoried over 7400 landslides from twelve agencies and/or data sources in a systematic and standardized format. Landslide events, once cataloged, were attributed with an extensive list of parameters summarizing topography, geology, soils, recent weather history, and local mining history. These data are summarized into data tables compatible with modern analysis tools and directly shared with the public when possible. In addition, case studies describing the potential for use of landslide data are presented in the report. This data framework, in conjunction with parallel and complimentary efforts, is a strong foundation for increasingly data driven approaches to landslide mitigation and management in the region.

Abstract: Landslides are a major disruption to road networks and infrastructure in Southwestern Pennsylvania. A combination of rugged topography, clay-rich bedrock, complicated hydrogeology, and changing local climate results in numerous landslides across the region, particularly in areas where humans have modified the landscape. However, documentation of the spatial and temporal patterns of these landslides is spread across a wide range of government agencies and historical sources. This limits comprehensive planning efforts to address ongoing damage and mitigate potential future landslides. This project has inventoried over 7400 landslides from twelve agencies and/or data sources in a systematic and standardized format. Landslide events, once cataloged, were attributed with an extensive list of parameters summarizing topography, geology, soils, recent weather history, and local mining history. These data are summarized into data tables compatible with modern analysis tools and directly shared with the public when possible. In addition, case studies describing the potential for use of landslide data are presented in the report. This data framework, in conjunction with parallel and complimentary efforts, is a strong foundation for increasingly data driven approaches to landslide mitigation and management in the region.

Dr. Daniel Bain: dbain@pitt.edu

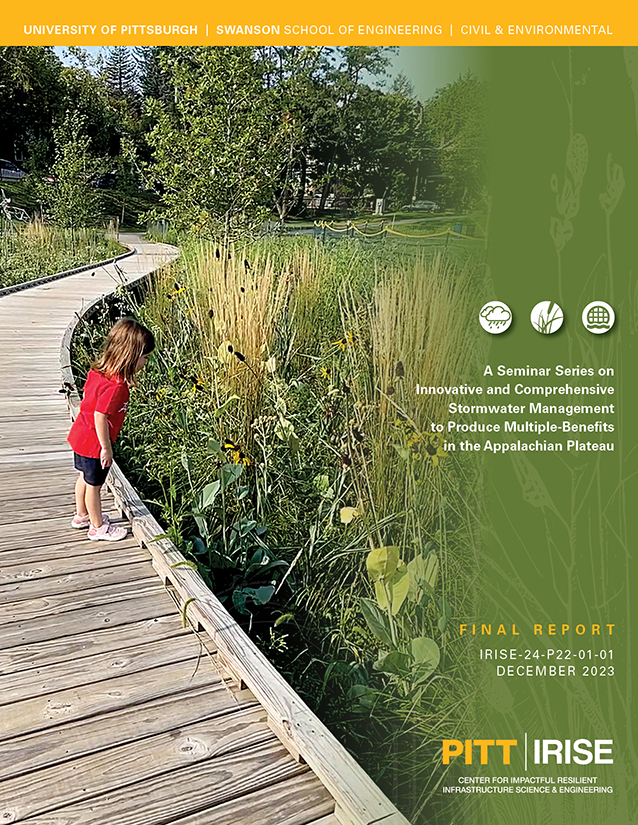

A SEMINAR SERIES ON INNOVATIVE AND COMPREHENSIVE STORMWATER MANAGEMENT

Abstract: A series of stormwater seminars will be held at the University of Pittsburgh to share collective and emerging knowledge about storm water control technologies, particularly green infrastructure approaches, effective cross-jurisdictional strategies, and scenarios of climate and regulatory strategy that are fundamental to successful management of stormwater runoff. These seminars will center approaches that address multiple objectives (e.g., decreased water flow and improved water quality) and facilitate communication about emerging, and potentially unorthodox, methods.

Dr. Daniel Bain: dbain@pitt.edu

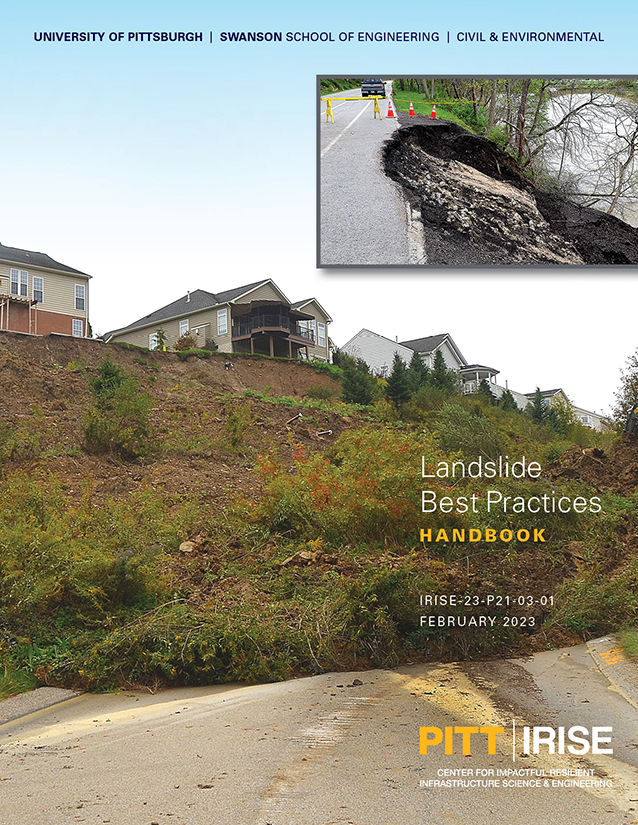

Landslide Best Practices

Abstract: The Landslide Best Practices Handbook was written to produce region-specific guidance for practicing geotechnical engineers and geologists who are engaged to mitigate adverse impacts from an active landslide or reduce the risk of landslide movement for infrastructure. Best practice guidelines for the life cycle of a landslide mitigation response including approach, characterization, assessment and mitigation are presented. A best practice framework for slope maintenance and slope management systems are also included.

Dr. Fatma Ciloglu, PE: fatma.ciloglu@mbakerintl.com

EXPLORING APPROACHES TO MANAGING LANDSLIDE RISKS WORKSHOP

Abstract: With the proliferation of landslides impacting transportation systems in western Pennsylvania, PennDOT Districts 11 and 12, the Central Office, FHWA and other members of the IRISE consortium identified the need for a forum to discuss recent/ongoing activities. The design of the workshop stressed current work to identify, anticipate, and remediate landslides. It provided an opportunity to share experiences and discuss best practice approaches. In the end, a discussion of future needs helped to prioritize activities and focus on the best use of available technology and resources to mitigate this critical regional problem.

121 individuals representing over 40 organizations in the public, private and academic sectors participated. Presentations during three workshop sessions addressed the following topics: Historical Perspective and Identification, Prediction, Remediation & Prioritization, and Managing Risks. The workshop concluded with a discussion of future needs by a panel consisting of leaders of western Pennsylvania government and academic institutions.

Dr. Anthony Iannacchione, PE, PG: ati2@pitt.edu

MATERIALS PROJECTS

Integrating Additive Manufacturing with Accelerated Bridge Construction Techniques

Abtrsatct: The main objective of this study is to investigate the feasibility of using 3D concrete printing (3DCP) for manufacturing prefabricated bridge elements in accelerated bridge construction (ABC) projects. A literature review is first conducted to survey the applications of 3DCP within the construction and building domains. This phase entails exploring diverse additive manufacturing techniques and materials relevant to construction. Incorporation of reinforcement in 3DCP stands as a significant challenge to advancing the 3DCP technology for ABC projects. Therefore, emphasis is placed on examining a range of reinforcement strategies for 3DCP. On this basis, multiple concrete beams are 3D printed with different reinforcement strategies. Three-point bending tests are conducted on the 3D printed specimens and conventionally cast counterparts to characterize their mechanical properties. The beam samples manufactured for the comparative study include cast plain beam, cast rebar-reinforced beam, plain beam with printed formwork, rebar-reinforced plain beam with printed formwork, plain beam with printed studs formwork, rebar-reinforced plain beam with printed studs formwork, fully printed plain beam, fully printed rebar-reinforced beam, and fully printed metal staple-reinforced beam. An important finding is that beams created using the reinforced 3DCP formwork with studs strategy exhibit the highest flexural strength compared to the beams fabricated using other casting and printing methods. Given the substantial costs associated with traditional concrete casting formwork, employing 3D printed formwork with studs can significantly reduce expenses while maintaining optimal performance. Therefore, this strategy is employed for the 3D printing of a small-scale prefabricated bridge element specifically identified as a pier cap. The results of the three-point bending tests indicate that the 3D printed pier cap demonstrates a comparable flexural strength to a conventionally cast prefabricated pier cap, while also exhibiting higher stiffness. The proposed experimental study reveals both promising possibilities and inherent limitations in the current 3DCP technology. Additional research directions and recommendations are presented to enhance the efficiency of 3DCP in ABC projects.

Abtrsatct: The main objective of this study is to investigate the feasibility of using 3D concrete printing (3DCP) for manufacturing prefabricated bridge elements in accelerated bridge construction (ABC) projects. A literature review is first conducted to survey the applications of 3DCP within the construction and building domains. This phase entails exploring diverse additive manufacturing techniques and materials relevant to construction. Incorporation of reinforcement in 3DCP stands as a significant challenge to advancing the 3DCP technology for ABC projects. Therefore, emphasis is placed on examining a range of reinforcement strategies for 3DCP. On this basis, multiple concrete beams are 3D printed with different reinforcement strategies. Three-point bending tests are conducted on the 3D printed specimens and conventionally cast counterparts to characterize their mechanical properties. The beam samples manufactured for the comparative study include cast plain beam, cast rebar-reinforced beam, plain beam with printed formwork, rebar-reinforced plain beam with printed formwork, plain beam with printed studs formwork, rebar-reinforced plain beam with printed studs formwork, fully printed plain beam, fully printed rebar-reinforced beam, and fully printed metal staple-reinforced beam. An important finding is that beams created using the reinforced 3DCP formwork with studs strategy exhibit the highest flexural strength compared to the beams fabricated using other casting and printing methods. Given the substantial costs associated with traditional concrete casting formwork, employing 3D printed formwork with studs can significantly reduce expenses while maintaining optimal performance. Therefore, this strategy is employed for the 3D printing of a small-scale prefabricated bridge element specifically identified as a pier cap. The results of the three-point bending tests indicate that the 3D printed pier cap demonstrates a comparable flexural strength to a conventionally cast prefabricated pier cap, while also exhibiting higher stiffness. The proposed experimental study reveals both promising possibilities and inherent limitations in the current 3DCP technology. Additional research directions and recommendations are presented to enhance the efficiency of 3DCP in ABC projects.

Dr. Amir Alavi: alavi@pitt.edu

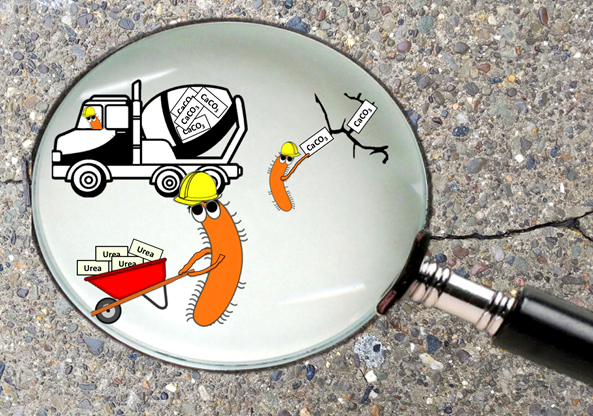

TOWARD USING MICROBES FOR SUSTAINABLE CONSTRUCTION MATERIALS: A FEASIBILITY STUDY

Abstract: Reinforced Concrete (RC) structures are susceptible to damage from long-term exposure to chloride-based compounds (e.g., from marine environments or deicers) and/or repeated freeze/thaw cycles. To mitigate damage and degradation from environmental loading, an estimated $16 billion per year is spent on the rehabilitation of RC structures using cementitious patching materials and/or chemical treatments, which contribute to pollution and require repeated application and maintenance.

Abstract: Reinforced Concrete (RC) structures are susceptible to damage from long-term exposure to chloride-based compounds (e.g., from marine environments or deicers) and/or repeated freeze/thaw cycles. To mitigate damage and degradation from environmental loading, an estimated $16 billion per year is spent on the rehabilitation of RC structures using cementitious patching materials and/or chemical treatments, which contribute to pollution and require repeated application and maintenance.

To mitigate these detrimental environmental impacts, this study evaluated the feasibility of increasing the durability, resiliency and sustainability of RC structures by using microbes to provide self-healing properties to prevent water and chloride ingress through structural and/or environmental cracking. State-of-the-art research has begun to explore microbial carbonate precipitation (MICP) for limestone, marble and, to a lesser extent, RC restoration. However, many challenges remain including:

- Finding non-pathogenic microbes capable of MICP;

- Developing methods to ensure microbial viability and even distribution throughout the material to be restored and;

- Creating and evaluating new RC formulations aimed at improving and or sustaining MICP.

This research focused on addressing these challenges, providing insight into the potential application of bio-restoration of RC, which will have far reaching applications for green building design and resilient and sustainable construction.

Dr. Sarah Haig: sjhaig@pitt.edu

MATERIAL COMPATIBLE REPAIRS (MCRS) FOR CONCRETE PAVEMENTS AND BRIDGE DECKS

Abstract: Partial-depth repairs are a rehabilitation method commonly performed on concrete pavements and bridge decks to restore the integrity of the structure. However, in the past, partial-depth repairs have not always achieved their expected life. Some contributing factors include poor construction practices and the use of nondurable repair materials. Another consideration not previously considered is the compatibility between the in-situ concrete and the repair material. Additional stress is generated at the interface between the repair material and the existing concrete when the two materials deform at differently rates. This has the potential to occur when the elastic modulus, thermal coefficient of expansion and/or the drying shrinkage of the repair material is significantly different from that of the existing concrete. The focus of this study is on investigating the effects of the incompatibility between the repair and existing concrete through a laboratory investigation and a computational study. Then a methodology was established for developing a performance engineered repair material (PERM) to be used for performing a material compatible repair (MCR). This is accomplished through the proper selection of a coarse aggregate so that stiffness and thermal compatibility between the repair material and the existing concrete is assured. Internal curing was also investigated to reduce the drying shrinkage of the repair material to minimize the potential for debonding between the repair and the older existing concrete.

Dr. Steven Sachs: sgs15@pitt.edu

Site Visits: 9/27/19 | 6/16/19

PAVEMENTS PROJECTS

Joint and Sealant Design Optimization

Abstract: As performance expectations and the design life continue to be increased for jointed plain concrete pavements (JPCP)s, it is important that the joints of the pavement meet these demands. The joint must also be properly sealed or it can serve as an entry point for moisture, deicing salts and incompressibles. This can lead to durability issues, erosion, pumping, faulting, spalling and blow-ups. Sealant performance is influenced by sealant material, joint reservoir design, and the timing and quality of the installation. A discussion on a holistic approach to joint design is provided along with an in-depth analysis on sealant and joint performance (Appendix A and B) and reservoir design (Appendix C) for JPCPs with 15-ft joint spacings. An extensive laboratory study was performed to evaluate three joint design/material combinations subjected to simulated joint opening/closing and vehicle load fatigue for a 42-year design life of a 15-ft JPCP (Appendix D). It was determined that Type II asphalt-filled and sealed reservoir designs exhibited greater cohesive and adhesive damage and were less watertight than the silicone sealed reservoir design after the 42 years of simulated service life.

Abstract: As performance expectations and the design life continue to be increased for jointed plain concrete pavements (JPCP)s, it is important that the joints of the pavement meet these demands. The joint must also be properly sealed or it can serve as an entry point for moisture, deicing salts and incompressibles. This can lead to durability issues, erosion, pumping, faulting, spalling and blow-ups. Sealant performance is influenced by sealant material, joint reservoir design, and the timing and quality of the installation. A discussion on a holistic approach to joint design is provided along with an in-depth analysis on sealant and joint performance (Appendix A and B) and reservoir design (Appendix C) for JPCPs with 15-ft joint spacings. An extensive laboratory study was performed to evaluate three joint design/material combinations subjected to simulated joint opening/closing and vehicle load fatigue for a 42-year design life of a 15-ft JPCP (Appendix D). It was determined that Type II asphalt-filled and sealed reservoir designs exhibited greater cohesive and adhesive damage and were less watertight than the silicone sealed reservoir design after the 42 years of simulated service life.

Dr. Julie Vandenbossche: jmv7@pitt.edu

Prediction of Dowel Corrosion and Effect on Performance of Concrete Pavements

Abstract: Corrosion of metallic dowel bars is a significant issue that can lead to a decrease in the long-term performance of jointed plain concrete pavements. The high chloride exposure from deicing agents coupled with moisture penetration at transverse joints creates a corrosive environment. Corrosion development is a complex phenomenon affected by both pavement design and climatic features. Current pavement performance prediction models are unable to account for dowel corrosion due to the limited understanding of this. This project was performed to improve the existing pavement performance models by incorporating the effect of dowel corrosion in the model framework. A review of available corrosion databases and corrosion prediction models was performed to inform the development of a novel accelerated dowel corrosion laboratory investigation. A range of dowel bars currently on the market were evaluated to quantify the development of corrosion and the effect on pavement performance. The results from the accelerated corrosion study were used to update the existing faulting prediction framework to account for the effect of corrosion on faulting development. The faulting model was calibrated with field performance data from in-service concrete pavements. The products of this project can be used to better account for the effect of corrosion on long-term dowel performance. Additionally, the revised faulting model enables the consideration of non-metallic dowels and alternative dowel coatings, which are being implemented in many long-life paving projects.

Abstract: Corrosion of metallic dowel bars is a significant issue that can lead to a decrease in the long-term performance of jointed plain concrete pavements. The high chloride exposure from deicing agents coupled with moisture penetration at transverse joints creates a corrosive environment. Corrosion development is a complex phenomenon affected by both pavement design and climatic features. Current pavement performance prediction models are unable to account for dowel corrosion due to the limited understanding of this. This project was performed to improve the existing pavement performance models by incorporating the effect of dowel corrosion in the model framework. A review of available corrosion databases and corrosion prediction models was performed to inform the development of a novel accelerated dowel corrosion laboratory investigation. A range of dowel bars currently on the market were evaluated to quantify the development of corrosion and the effect on pavement performance. The results from the accelerated corrosion study were used to update the existing faulting prediction framework to account for the effect of corrosion on faulting development. The faulting model was calibrated with field performance data from in-service concrete pavements. The products of this project can be used to better account for the effect of corrosion on long-term dowel performance. Additionally, the revised faulting model enables the consideration of non-metallic dowels and alternative dowel coatings, which are being implemented in many long-life paving projects.

Dr. Julie Vandenbossche: jmv7@pitt.edu

Seal Coat for Asphalt Pavements: Best Practices and Experience

Abstract: Sealcoating (also known as, chip seals) is one of the most commonly used pavement preventive maintenance activity for asphalt pavements, especially for low volume roadways. This study conducted a comprehensive evaluation of the current sealcoating practices across Pennsylvania through review of current literature and specifications, survey of state and local transportation entities in Pennsylvania and through series of interviews. In addition to seal-coating this study also conducted literature review and surveys on other asphalt pavement preventive maintenance activities in Pennsylvania. Using the review and current agency practices, best practices regarding sealcoating with respect to their use, application timing and, materials and construction specifications have been identified.

Abstract: Sealcoating (also known as, chip seals) is one of the most commonly used pavement preventive maintenance activity for asphalt pavements, especially for low volume roadways. This study conducted a comprehensive evaluation of the current sealcoating practices across Pennsylvania through review of current literature and specifications, survey of state and local transportation entities in Pennsylvania and through series of interviews. In addition to seal-coating this study also conducted literature review and surveys on other asphalt pavement preventive maintenance activities in Pennsylvania. Using the review and current agency practices, best practices regarding sealcoating with respect to their use, application timing and, materials and construction specifications have been identified.

Dr. Eshan Dave: eshan.dave@unh.edu

Three-Dimensional Micro-Mechanical Characterization of Concrete Vibration

Abstract: Vibration is a crucial step in slipform paving during construction; however, the specific usage scenarios have led to an unclear understanding of the relationship between vibratory energy input and the quality of concrete consolidation. Thus, developing a comprehensive evaluation system to assess and characterize the vibratory behavior in slipform paving would facilitate the creation of practical guidelines for optimizing the paving process under various conditions. This study explores how vibration energy affects the distribution of air, coarse aggregate, and mortar of concrete as well as providing a frame for homogeneity assessment. Initially, the study models the mechanical response of coarse aggregate to vibration energy during slipform paving, utilizing paver consolidation simulation (PaCS). The coarse aggregate is recognized and segmented with advanced computer vision techniques. Subsequently, "virtual aggregates" resembling real aggregates in morphology were generated using spherical harmonic expansion and random fields and reconstruct mesoscale model using discrete element simulation to model the optimal spatial distribution of aggregates. Then, the outcomes from concrete paving simulation experiments and numerical simulations are compared to establish a model explicitly correlating vibration energy input with concrete consolidation quality.

Abstract: Vibration is a crucial step in slipform paving during construction; however, the specific usage scenarios have led to an unclear understanding of the relationship between vibratory energy input and the quality of concrete consolidation. Thus, developing a comprehensive evaluation system to assess and characterize the vibratory behavior in slipform paving would facilitate the creation of practical guidelines for optimizing the paving process under various conditions. This study explores how vibration energy affects the distribution of air, coarse aggregate, and mortar of concrete as well as providing a frame for homogeneity assessment. Initially, the study models the mechanical response of coarse aggregate to vibration energy during slipform paving, utilizing paver consolidation simulation (PaCS). The coarse aggregate is recognized and segmented with advanced computer vision techniques. Subsequently, "virtual aggregates" resembling real aggregates in morphology were generated using spherical harmonic expansion and random fields and reconstruct mesoscale model using discrete element simulation to model the optimal spatial distribution of aggregates. Then, the outcomes from concrete paving simulation experiments and numerical simulations are compared to establish a model explicitly correlating vibration energy input with concrete consolidation quality.

Dr. Alessandro Fascetti: fascetti@pitt.edu

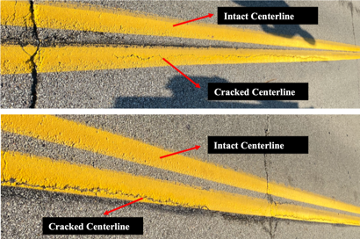

Preliminary Evaluation of Pavement Surface Distresses Related to Pavement Markings.

Abstract: Since road marking research is traditionally focused on the life-cycle performance of various marking materials in terms of durability and visibility, little is known about the effect of surface markings on pavement performance. Nevertheless, transportation agencies have reported the presence of pavement distresses, such as cracking and raveling, under or along pavement markings. This project investigated whether pavement markings cause pavement surface deterioration. Pavement sections with distresses potentially caused by pavement markings were identified. Visual surveys were performed to identify whether the surface distresses were located directly below or in the vicinity of the markings, relating the damaged area to the overall surface condition. Nondestructive testing was performed to evaluate the marking/pavement condition. Finite element modeling was conducted to evaluate the potential effect of temperature differentials on the interaction between markings and pavement surfaces. Results strongly indicate the issues with longitudinal joint compaction are the main culprit for pavement deterioration around longitudinal pavement markings. Recommendations regarding longitudinal joint construction and evaluation as well as pavement marking installation were proposed to avoid early pavement marking deterioration.

Abstract: Since road marking research is traditionally focused on the life-cycle performance of various marking materials in terms of durability and visibility, little is known about the effect of surface markings on pavement performance. Nevertheless, transportation agencies have reported the presence of pavement distresses, such as cracking and raveling, under or along pavement markings. This project investigated whether pavement markings cause pavement surface deterioration. Pavement sections with distresses potentially caused by pavement markings were identified. Visual surveys were performed to identify whether the surface distresses were located directly below or in the vicinity of the markings, relating the damaged area to the overall surface condition. Nondestructive testing was performed to evaluate the marking/pavement condition. Finite element modeling was conducted to evaluate the potential effect of temperature differentials on the interaction between markings and pavement surfaces. Results strongly indicate the issues with longitudinal joint compaction are the main culprit for pavement deterioration around longitudinal pavement markings. Recommendations regarding longitudinal joint construction and evaluation as well as pavement marking installation were proposed to avoid early pavement marking deterioration.

Dr. Lev Khazanovich: Lev.K@pitt.edu

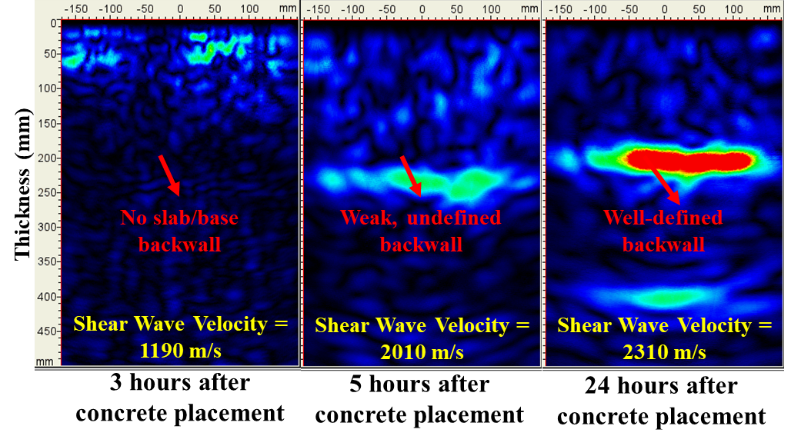

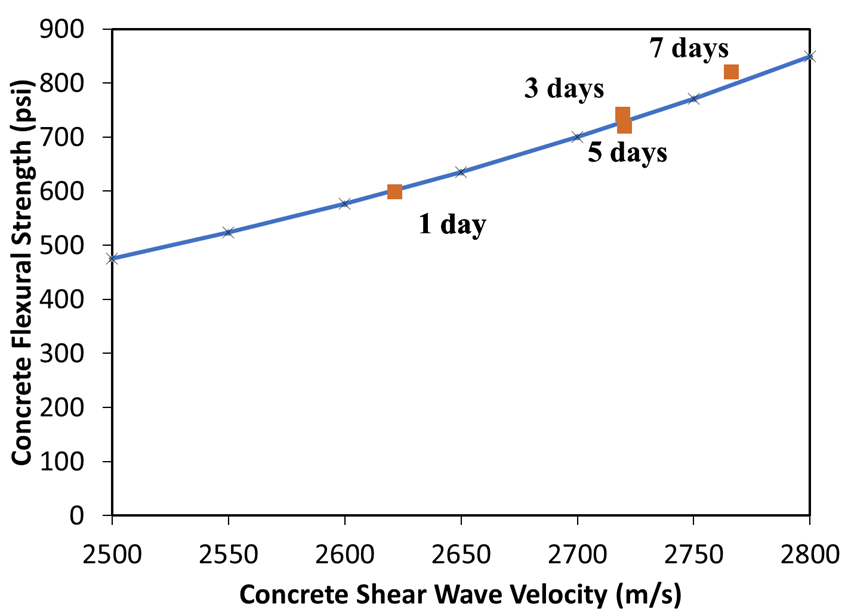

EARLY OPENING OF CONCRETE PAVEMENTS TO TRAFFIC

Abstract: Earlier opening of concrete pavement to traffic without detriment to short- and long-term pavement performance can reduce construction time and improve driver satisfaction. Improving concrete strength estimations in the field and strength gain predictions as well as early age damage modeling are keys to optimizing openings to traffic. To evaluate the estimation of concrete strength, laboratory and field studies were conducted using maturity and ultrasonic tomography. It was found that both methods were efficient and resulted in reasonable concrete strength estimations for in-situ pavements, but ultrasonic tomography was found to have advantages over the maturity method, such as improved correlation and mobility.

A strength gain prediction model was created using both nondestructive methods that combined the benefits of ultrasonic tomography for strength estimation with the predictive ability of the maturity method for future strength development prediction. A mechanistic-based early opening damage analysis procedure incorporating the combined nondestructive testing technique for strength evaluation was developed to predict the effect of early loading on transverse cracking and dowel bar performance for Pennsylvania climatic conditions. A web-based tool was created to facilitate the implementation of this procedure for determining the optimal time when paving projects can be opened to traffic without significant damage.

User cost analysis showed that early opening a pavement to traffic would have significant benefits on urban arterial roadways and a minor effect on freeways.

Dr. Lev Khazanovich: Lev.K@pitt.edu

DEVELOPMENT OF SIMPLIFIED MECHANISTIC-EMPIRICAL DESIGN TOOL FOR PENNSYLVANIA RIGID PAVEMENTS

Abstract:

To accelerate the implementation of AASHTO Mechanistic-Empirical Pavement Design Guide (MEPDG) in Pennsylvania, a simplified ME design method and a localized design tool are developed for concrete pavement. The new procedure, PittRigid ME, is based on the AASHTO MEPDG design procedure, but restricts design input parameters to the most influential and relevant for Pennsylvania conditions. It matches the MEPDG predicted performance at a fraction of the computational cost.

PittRigid ME can be used to predict pavement performance (i.e. fatigue cracking and joint faulting) or determine the concrete slab thickness and dowel diameters for given performance criteria and reliability level. It simplifies design process and reduces potential design errors from improper use of the AASHTOWare Pavement ME software.

The development of PittRigid ME procedure is documented in this report.

An installation file for the PittRigid ME application can be downloaded here.

Dr. Lev Khazanovich: Lev.K@pitt.edu

WORKER SAFETY PROJECTS

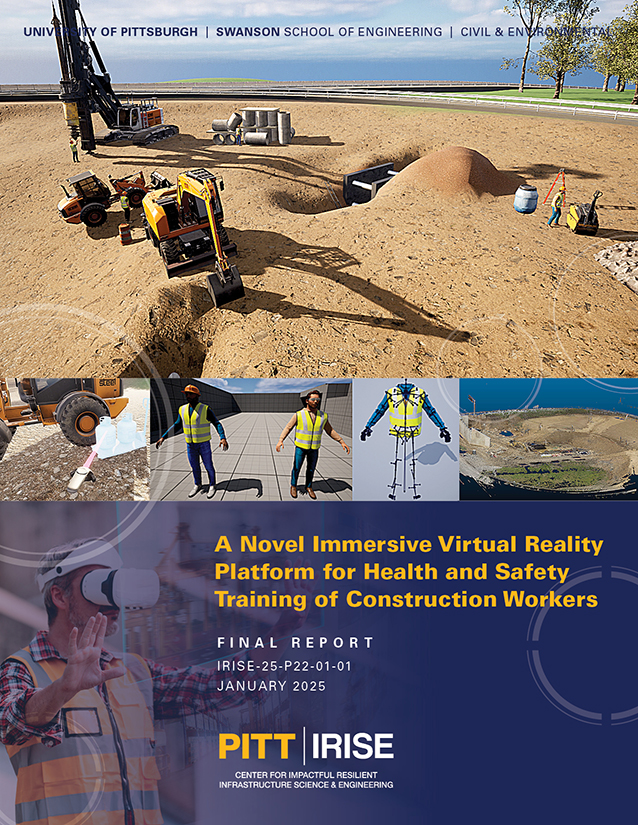

A Novel and Immersive Virtual Reality Platform for Health & Safety Training of Construction Workers

Abstract: Health and safety (H&S) training in the construction industry is paramount, given the sector's high injury and fatality rates. Traditional training tends to exhibit over-reliance on passive methods of instruction, bringing challenges associated with knowledge retention and engagement. This study leverages virtual reality (VR) to enhance H&S training through immersive virtual environments (IVE)s and serious gaming. Laser scanning data captured from an active highway construction site created a highly realistic IVE. This environment was then leveraged to build a virtual reality platform containing modules for construction safety training using Unreal Engine 5 (UE5). Users navigate these modules, interacting with objects to identify hazards and learn about safety guidelines. All platform construction scenarios are parametric, so context-specific training can be implemented. Evaluation of the module's realism, usability, and potential for enhancing traditional training programs was performed through beta testing on a user group composed of experts in both construction safety and computer science. The results of this research demonstrate the potential of VR in creating immersive and engaging training experiences, which could lead to improved safety performance outcomes in highway construction operations.

Abstract: Health and safety (H&S) training in the construction industry is paramount, given the sector's high injury and fatality rates. Traditional training tends to exhibit over-reliance on passive methods of instruction, bringing challenges associated with knowledge retention and engagement. This study leverages virtual reality (VR) to enhance H&S training through immersive virtual environments (IVE)s and serious gaming. Laser scanning data captured from an active highway construction site created a highly realistic IVE. This environment was then leveraged to build a virtual reality platform containing modules for construction safety training using Unreal Engine 5 (UE5). Users navigate these modules, interacting with objects to identify hazards and learn about safety guidelines. All platform construction scenarios are parametric, so context-specific training can be implemented. Evaluation of the module's realism, usability, and potential for enhancing traditional training programs was performed through beta testing on a user group composed of experts in both construction safety and computer science. The results of this research demonstrate the potential of VR in creating immersive and engaging training experiences, which could lead to improved safety performance outcomes in highway construction operations.

Dr. Alessandro Fascetti: fascetti@pitt.edu

REMOTE-CONTROLLED TECHNOLOGY ASSESSMENT FOR SAFER CONSTRUCTION

Abstract: Pavement construction, inspection and maintenance are activities that often require workers near heavy equipment, traffic and dangerous materials. This proximity to potential hazards along with the characteristics of highway and street work zones - transient and restricted areas - increases the possibility of accidents and near-misses. Recent developments in remote-controlled technology can provide workers and inspectors the ability to conduct activities from a safer distance. This project aimed at scanning and evaluating several promising remote-controlled technologies that could be used to improve safety in highway and streets work zones. The technology scanning disclosed over twenty technologies in several levels of development that met this goal. Three technologies were selected for a more detailed review: the Remote-Controlled Ground Penetrating Radar (GPR) for Asphalt Density, the Automated Real-Time Thermal Profiling for Asphalt Paving, and the Autonomous Impact Protection Vehicle. Each technology was evaluated not only based on safety features but also on productivity, data processing, and, especially, requirements for implementation. Workshops with vendors and leading experts were promoted for each technology. Field demonstrations were conducted for the Density Profiling System for determining in-situ asphalt density. Finally, several recommendations for implementation of the selected technologies were provided.

Abstract: Pavement construction, inspection and maintenance are activities that often require workers near heavy equipment, traffic and dangerous materials. This proximity to potential hazards along with the characteristics of highway and street work zones - transient and restricted areas - increases the possibility of accidents and near-misses. Recent developments in remote-controlled technology can provide workers and inspectors the ability to conduct activities from a safer distance. This project aimed at scanning and evaluating several promising remote-controlled technologies that could be used to improve safety in highway and streets work zones. The technology scanning disclosed over twenty technologies in several levels of development that met this goal. Three technologies were selected for a more detailed review: the Remote-Controlled Ground Penetrating Radar (GPR) for Asphalt Density, the Automated Real-Time Thermal Profiling for Asphalt Paving, and the Autonomous Impact Protection Vehicle. Each technology was evaluated not only based on safety features but also on productivity, data processing, and, especially, requirements for implementation. Workshops with vendors and leading experts were promoted for each technology. Field demonstrations were conducted for the Density Profiling System for determining in-situ asphalt density. Finally, several recommendations for implementation of the selected technologies were provided.

Dr. Lev Khazanovich: Lev.K@pitt.edu

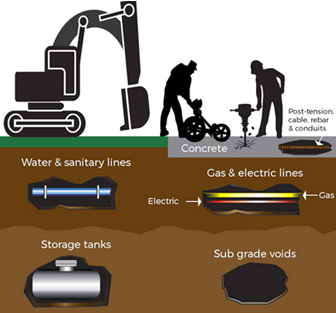

Investigating New Underground Utility Location Technologies and Novel Methods to Improve the Safety and Efficiency of Highway Construction

Abstract: Recent advancements in underground utility detection technologies, particularly ground-penetrating radar (GPR), have revolutionized the ability to locate underground utilities, crucial for worker safety and highway construction efficiency. GPR offers faster and more accurate data acquisition through multi-channel devices and various wave frequencies. Software developments have eliminated the need for extensive training, making GPR more accessible. Moreover, data interpretation and visualization techniques have been refined to enhance location accuracy and user-friendliness. In conjunction with GPR, acoustic methods are being explored to address limitations of traditional technologies. Although no single technology can meet all objectives simultaneously, a combination of devices can be employed based on site conditions. Factors such as pipe material, environmental conditions, and the presence of other utilities or underground objects must be considered. This study evaluated several GPR-based devices and recommends three equipment types for different construction stages, aligned with objectives outlined by local contractors and agencies.

Abstract: Recent advancements in underground utility detection technologies, particularly ground-penetrating radar (GPR), have revolutionized the ability to locate underground utilities, crucial for worker safety and highway construction efficiency. GPR offers faster and more accurate data acquisition through multi-channel devices and various wave frequencies. Software developments have eliminated the need for extensive training, making GPR more accessible. Moreover, data interpretation and visualization techniques have been refined to enhance location accuracy and user-friendliness. In conjunction with GPR, acoustic methods are being explored to address limitations of traditional technologies. Although no single technology can meet all objectives simultaneously, a combination of devices can be employed based on site conditions. Factors such as pipe material, environmental conditions, and the presence of other utilities or underground objects must be considered. This study evaluated several GPR-based devices and recommends three equipment types for different construction stages, aligned with objectives outlined by local contractors and agencies.

Dr. Lev Khazanovich: Lev.K@pitt.edu

IDENTIFYING MAJOR CAUSES OF CONSTRUCTION ACCIDENTS

Abstract: According to the National Institute for Occupational Safety and Health (NIOSH), every year more than 100 workers are killed and 20,000 are injured in the highway and street construction industry. Almost half of these accidents are from the movement of construction equipment and other construction-related activities. This project will identify and rank dangerous scenarios, taking into consideration near-misses, in highway and street construction in Pennsylvania. It will develop recommendations for avoiding or minimizing dangerous scenarios in the future and provide qualitative information for the improvement of safety training and development of safety-related equipment.

Abstract: According to the National Institute for Occupational Safety and Health (NIOSH), every year more than 100 workers are killed and 20,000 are injured in the highway and street construction industry. Almost half of these accidents are from the movement of construction equipment and other construction-related activities. This project will identify and rank dangerous scenarios, taking into consideration near-misses, in highway and street construction in Pennsylvania. It will develop recommendations for avoiding or minimizing dangerous scenarios in the future and provide qualitative information for the improvement of safety training and development of safety-related equipment.

Dr. Lev Khazanovich: Lev.K@pitt.edu