NANOMANUFACTURING

Nanoscience and nanotechnology are the study and application of extremely small things and can be used across all the other science fields, such as chemistry, biology, physics, materials science, and engineering.The University of Pittsburgh Nanoscale Fabrication & Characterization Facility (NFCF) is designed to support fabrication and characterization of nanoscale materials and structures, and integration of devices at all length scales. The facility houses advanced equipment with core nano-level (20 nm or below) capability for fabrication and characterization, including electron-beam lithography system, dual-beam system, plasma etching, thin film deposition, TEM, multifunctional scanning probe station, modular XRD, etc.

MOSTAFA BEDEWY

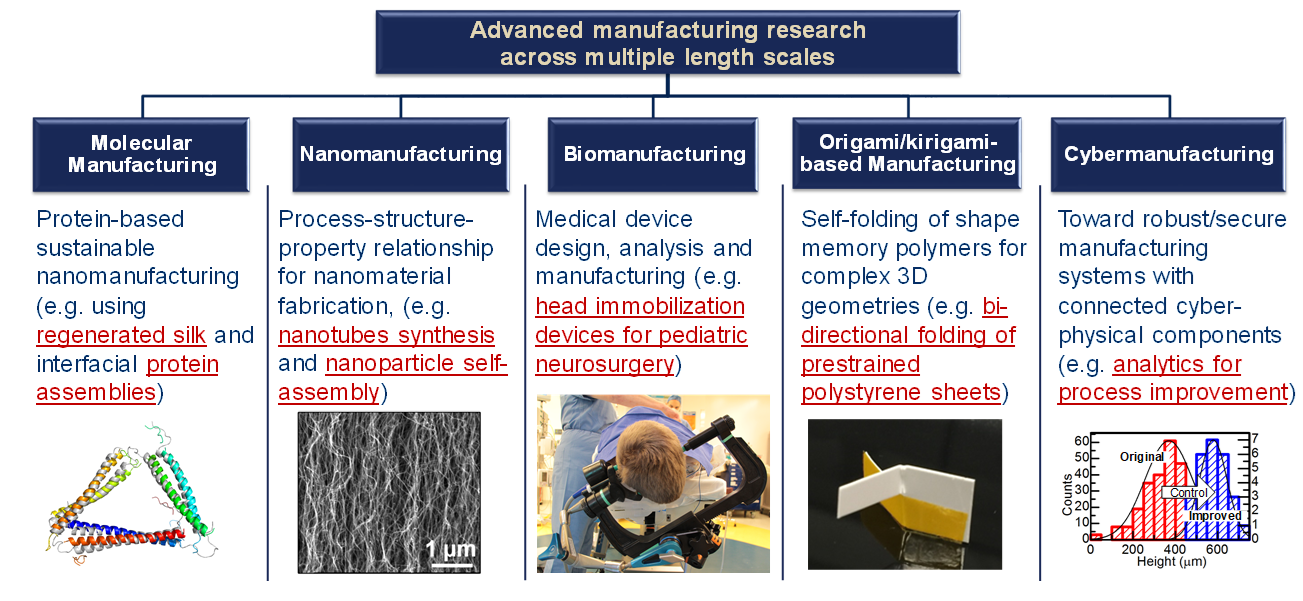

In the NanoProduct Lab (Bedewy Research Group), we leverage precision engineering, biomimetic/bio-inspired designs, and quantitative tools to tackle fundamental research questions at the interface between nanoscience, biotechnology, and manufacturing engineering. Bridging the gap between promising proof-of-concept results (in lab-scale environment) and mass-produced products (in industry), our work aims at creating novel solutions that impact major societal challenges in areas related to energy, healthcare, and the environment.

mbedewy@pitt.edu

http://nanoproductlab.org/

KEVIN CHEN

Dr. Kevin Chen's research focuses on scalable 3D laser manufacturing from nanoscale to macroscale. Sensor fused additive manufacturing.

TEVIS JACOBS

![]()

The focus of the Jacobs Research Group is to reveal the atomic-scale processes governing the mechanical and transport properties of surfaces and interfaces at the nanoscale. Contacting surfaces are of critical importance in advanced nanoscale applications, including micro-/nano-electromechanical systems, manufacturing schemes, and microscopy applications. The function of such applications depends on the ability to precisely predict and control contact parameters such as contact stiffness, contact area, adhesion, and electrical contact resistance. Our group uses novel combinations of scanning probe microscopy, electron microscopy, and mechanical testing techniques to interrogate the mechanical behavior of contacts between nanoscale bodies, and the interdependence between mechanical properties and functional properties of the contact.

Mechanical and transport properties of individual small-scale contacts: Scanning probe techniques are used inside of a transmission electron microscope (TEM). By simultaneously achieving Angstrom-scale spatial resolution and nanonewton force resolution, we can interrogate individual nanoscale bodies – including the formation and separation of their contact, and its evolution under load. Using an in situ TEM nanomanipulator with specialty scanning probe microscopy tips, we can simultaneously measure transport properties – such as electrical contact resistance and heat transfer. This enables the quantitative interrogation of the load-dependence of functional properties, and the effects of surface

www.engineering.pitt.edu/JacobsLab/

tjacobs@pitt.edu

PRASHANT KUMTA

Work in Professor Prashant N. Kumta’s laboratory focuses on innovative synthesis, fabrication and additive manufacturing of novel materials and architectures for energy and biotechnologies. Specifically, research is directed at fundamental characterization and obtaining a scientific understanding of structure and property relationships of novel materials and platforms for batteries, fuel cells, electrocatalysts, photoelectrocatalysts, degradable scaffolds, functionalization of scaffolds for tissue regeneration, drug and protein delivery, non-viral gene delivery, as well as embryonic stem cell differentiation.

SANGYEOP LEE

Dr. Sangyeop Lee as studied nano-to-microscale thermal transport using theory and simulation. Current focus is on the thermal transport during phase transition.

PAUL LEU

Dr. Paul W. Leu’s research group focuses on combining simulations and experiments to discover and evaluate new advanced materials for optoelectronic devices and antibacterial surfaces. His lab simulates and fabricates various nanomaterials, such as metal nanomeshes, nanosphere coatings, nano-structured hazy glass, nanowires, and nanoholes for applications such as solar cells. His re-search seeks to understand the various process—structure—property relationships of these nano-materials to enable functionalities such as nanophotonic light scattering, plasmonic light trapping, antireflection, self-cleaning, and high durability.

LAMP has worked with various researchers at UPMC to evaluate new nanostructured surfaces for anti-biofouling (preventing adhesion), antibactericidal (killing bacteria), self-cleaning, and durability properties. The lab is determining how various mechanisms such as surface energy, topography, surface chemistry may contribute to these antibacterial properties.

Paul Leu is also the Pitt director of the MDS-Rely, an NSF IUCRC that is currently in the planning phase. The goal of MDS-Rely is to apply data science-informed research to better understand the reliability and performance lifetime of essential materials. It has the potential to transform this field in creating new technologies that enable unprecedented lifetimes, durability in extreme environments, and understanding of various degradation and failure mechanisms.

www.pitt.edu/~pleu/Research/index.html

http://mds-rely.org/

pleu@pitt.edu

RAVI SHANKAR

![]()

Our research focuses on understanding the behavior of materials over length-scales ranging from the macro to the nano, as a function of composition, thermomechanical history and microstructural design. Research interests include thermal and mechanical behavior of nanocrystalline metals and amorphous alloys, mechanics and property evolution in nano and micro-manufacturing processes and design of multi-functional materials.

Multifunctional Nanograined Materials: We are studying how nano-scale grain structures can demonstrate novel functional properties that accompany their enhanced mechanical properties. We are examining scalable approaches for creating such microstructures at surfaces and in bulk-forms in Al, Mg and Ti alloys and their technological implications for structural and biomedical applications.

Direct Transduction of Photonic Energy into Mechanical Work: Azobenzene-functionalized polymers can transduce light directly into mechanical work either via trans-cis isomerization or via the trans-cis-trans reorientation of the azo groups. We are examining approaches centered on design of novel compositions and mechanical designs for enhancing the efficiency of this transduction and maximizing the achievable power densities.

Hierarchical Nanostructured Surfaces: Surfaces with hierarchies composed of nano-scale structures on micro-scale features endow novel functionalities in several instructive illustrations from the natural world. We are working on new direct-write approaches for the scalable manufacture of such complex hierarchies in polymeric materials for engineering applications.

Mechanics of Deformations at the Micro-Scale: Understanding the implications of the stochasticity, size-effects and constitutive properties of deformation of metals at the micrometer and sub-micrometer length-scales is critical for controlling process and product outcomes in mechanical microforming. We are working on new experimental paradigms for exploring the mechanics of deformation and microstructural consequences in microdeformation configurations using a custom-designed platform that can perform multiaxial manipulation inside an electron microscope.