Research

Overview

With the fast growth of nanotechnology, understanding the surface properties of nano-sized materials becomes more and more critical since these materials, e.g., graphene, have no bulk phase but surfaces. From the fundamental viewpoint, the governing mechanisms at nanoscale and interfaces are very different from bulk materials. For practical applications, because the integration of nano-sized materials with other materials is always necessary in real-life device fabrication, the capability of manipulating the surface and interfacial properties is the key to the manufacture and performance of the device. The research in LI Lab focuses on surface, interface & nanomaterials. Standing at the interface between surface science and nano-materials, we aim to uncover the governing mechanisms of the surface properties of various nano-sized materials, ranging from graphene, ionic liquids to functional polymers. Meanwhile, we apply the fundamental understandings gained here on real-life applications, e.g., lubrications and water treatment.

Understanding The Graphene/2D Materials From The Surface

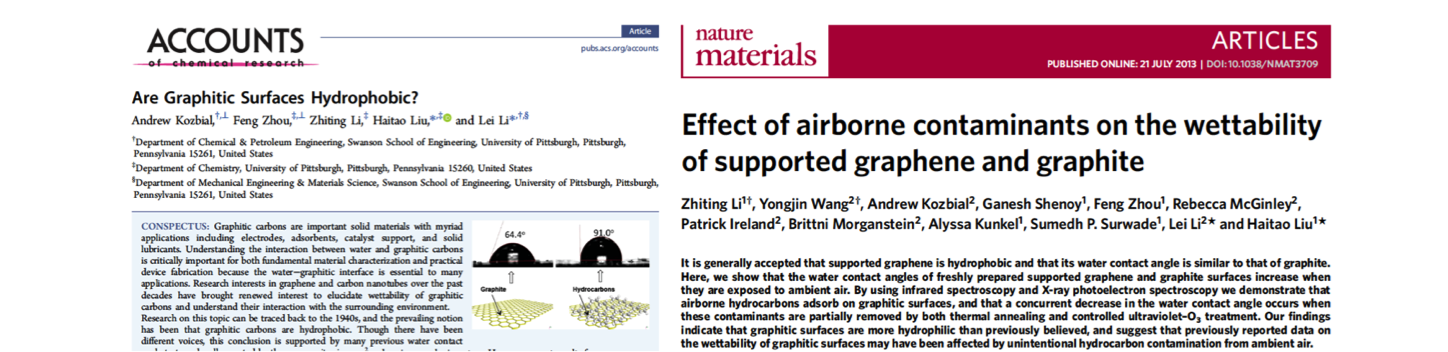

In the past 70+ years, it has been well accepted that the graphitic surfaces are hydrophobic. Recent experimental and theoretical works also showed that supported graphene is hydrophobic and that its water contact angle is similar to that of graphite. However, the research in our labs showed that the water contact angles of freshly prepared supported graphene and graphite surfaces are significantly lower than previously reported values and increase gradually when they are exposed to ambient air. By using infrared spectroscopy, X-ray photoelectron spectroscopy and ellipsometry we have demonstrated that the graphene/graphite surface is intrinsically mildly hydrophilic and the long-believed “hydrophobicity” is due to airborne hydrocarbon contamination. This research challenged long-established concept on the intrinsic water wettability of graphitic surfaces and potentially will completely change the way people model, manufacture and modify the graphitic materials. More recent works in our labs also showed that the similar contamination effects have occurred to other 2D materials, e.g., MoS2, as well, indicating 2D layered materials have higher surface energy than previously believed in general.

Publications:

- Hurst, J.; Kim, M. A.; Peng, Z.; Li, L.* and Liu, H.* “Assessing and mitigating surface contamination of carbon electrode materials”, Chem. Mater., (IF = 10.159), 2019, 31, 7133-7142

- Hurst, J.; Li, L. and Liu, H.* “Adventitious hydrocarbons and the graphite-water interface”, Carbon (IF = 6.832), 2018, 134, 464-469

- Peng, Z.; Yang, R. Kim, M., Li L.* and Liu, H.* “Influence of O2, H2O and airborned hydrocarbons on the properties of selected 2D materials” RSC Adv. (IF =3.485), 2017, 7(43), 27048-27057.

- Liu, H.* and Li, L.* “Graphitic materials: intrinsic hydrophilicity and its implications”, Extreme Mechanics Letters, 2017, in press.

- Kozbial, A.; Trouba, C. and Li, L.* “Characterization of the intrinsic water wettability of graphite with contact angle measurement: effect of defects on the static and dynamic contact angles”, Langmuir (IF = 4.210), 2017, 33(4), 959-967

- Kozbial, A.; Zhou, F.; Li, Z.; Liu, H.* and Li, L.* “Are graphitic surfaces hydrophobic”, Acc. Chem. Res. (IF = 22.003), 2016, 49(12), 2765-2773

- Li, Z.; Kozbial, A.; Nioradze, N; Parobek, D.; Shenoy, G.; Salim, M.; Amemiya, S.; Li, L.* and Liu, H.* “Water protects graphitic surface from airborne hydrocarbon contamination”, ACS Nano (IF = 14.486) 2016, 10(1), 349-359

- Kozbial, A.; Gong, X.; Liu H. and Li, L.* “Understanding the intrinsic water wettability of molybdenum disulfide (MoS2)”, Langmuir (IF = 4.210), 2015, 31(30), 8429-8435

- Kozbial, A.; Li, Z.; Conaway, C.; McGinley, R.; Dhingra, S.; Vahdat, V.; D’Urso, B.; Liu, H.* and Li, L.* “Study on the surface energy of graphene by contact angle measurements”, Langmuir (IF = 4.210) , 2014, 30, 8598-8606

- Kozbial, A.; Li, Z.; Sun, J.; Gong, X.; Wang, Y.; Xu, H.; Liu, H.* and Li, L.* “Understanding the intrinsic water wettability of graphite”, Carbon (IF = 6.832), 2014, 74, 218-225

- Li, Z.; Wang, Y.; Kozbial, A.; Shenoy, G.; Zhou, F.; McGinley, R.; Ireland, P.; Morganstein, B.; Kunkel, A.; Surwade, S. P.; Li, L.* and Liu, H.* “Effect of airborne contaminants on the wettability of supported graphene and graphite”, Nature Mater. (IF = 45.772), 2013, 12, 925 (Highlighted by Nature Mater.)

- Zhou, F.; Li, Z.; Shenoy, G.; Li L. and Liu, H.* “Enhanced Room-Temperature Corrosion of Copper in the Presence of Graphene”, ACS Nano (IF = 14.486), 2013, 7(8), 6939-6947

IONIC LIQUIDS CONFINED TO SOLID SURFACES

Since many applications of room temperature ionic liquids (RTILs) are related to their performance near a solid surface, it is critical to uncover the underlying mechanism of the molecular-level arrangement of RTIL molecules at the RTIL/solid interface. We have investigated RTIL/silica, RTIL/mica and RTIL/carbon systems. At RTIL/ceramic interfaces, our research highlights the importance of sub-nanometer thick water and provides a new angle to manipulate the molecular arrangement of RTIL. At RTIL/graphite interface, we have identified the π-π+ stacking as the governing mechanism of the extended layering and designed nanometer-thick lubricant based on this learning.

Publications:

- Wang, B.; Moran C.; Lin, D. Huan, T.; Gage, E. and Li, L.* “Nanometer-thick fluorinated ionic liquids (ILs) as media lubricants for data storage devices”, ACS Appl. Nano Mater.,2019, 2, 5260-5265

- Gong, X*; Wang, B. and Li, L.* “Spreading of nanodroplets of ionic liquids on the mica surface”, ACS Omega, 2018, 3, 16398-16402.

- Gong, X*; Wang, B.; Kozbile, A. and Li, L.* “From molecular arrangement to macroscopic wetting of ionic liquids on the mica surface: Effect of humidity”, Langmuir (IF = 4.210), 2018, 34, 12167-12173.

- Lertola, A.; Wang, B. and Li, L.* “Understanding the friction of nanometer-thick fluorinated ionic liquids (ILs)”, Ind. Eng. Chem. Res. (IF = 3.141), 2018, 57(34), 11681-11685.

- Gong, X.* and Li, L.* “Nanometer-thick ionic liquids as boundary lubricants”, Adv. Engr. Mater. (IF = 2.319) 2018, 1700617 (Invited review).

- Gong, X. and Li, L.* “Understanding the wettability of nanometer-thick room temperature ionic liquids (RTILs) on solid surfaces”, Chin. Chem. Lett.(IF = 1.932)2017, 55(22), 6391-6397 (Invited review).

- Gong, X.; West, B.; Taylor, A. and Li, L.* “Study on nanometer-thick room-temperature ionic liquids (RTILs) for applications as the media lubricant in heat-assisted magnetic recording (HAMR)”, Ind. Eng. Chem. Res. (IF = 2.718) 2016, 55(22), 6391-6397

- Gong, X.; Kozbial, A. and Li, L.* “What causes extended layering of ionic liquids on the mica surface?”, Chem. Sci. (IF = 9.155), 2015, 6, 3478-3482

- Gong, X.; Kozbial, A.; Rose, F. and Li, L.* “Effect of π–π+ Stacking on the Layering of Ionic Liquids Confined to an Amorphous Carbon Surface”, ACS Appl. Mater. Interfaces. (IF = 7.332), 2015, 7(13), 7078-7081

- Gong, X.; Frankert, S.; Wang, Y. and Li, L.* “Thickness-dependent molecular arrangement and topography of ultrathin ionic liquid films on a silica surface”, Chem. Commun. (IF = 6.628), 2013, 49(71), 7803-7805

NANOMETER-THICK POLYMER COATINGS

Nanometer-thick polymer coatings are highly desirable in many important applications, such as information storage, solar panel, oil-water separation, anti-fogging and MEMS/NEMS. In these applications, the control of surface energy is the key to the desired performance, e.g., low friction and high hydrophobicity. We have investigated the structure-property relationship and thus developed coatings with various wettability, e.g., from superhydrophobic to simultaneously oleophobic/hydrophilic. We also established a unique photochemical approach, which is easy-to-scale and cost-effective, to fabricate simultaneously oleophobic/hydrophilic coatings. Moreover, we have developed a method to prepare the environmentally friendly coating with the desired low surface energy.

Publications:

- Wang, Y.; Gong, X.; You, C. and Li, L.* “A nanometer-thick, mechanically robust and easy-to-fabricate simultaneously oleophobic/hydrophilic polymer coating for oil-water separation”, Ind. Eng. Chem. Res.(IF = 3.141), 2018, 57, 15395-15399.

- Kozbial, A.; Guan, W. and Li, L.* “Manipulating the molecular conformation of a nanometer-thick environmentally friendly coating to control the surface energy” J. Mater. Chem. A (IF = 8.262), 2017, 5, 9752-9759.

- Wang Y.; Dugan M.; Urbaniak B. and Li, L.* “A nanometer-thick simultaneously oleophobic/hydrophilic polymer coating fabricated via a photochemical approach”, Langmuir (IF = 4.210) , 2016, 32(26), 6723-6729

- Wang Y.; Knapp J.; Legere A.; Raney, J. and Li L.* “Effect of end-groups on simultaneous oleophobicity/hydrophilicity and anti-fogging performance of nanometer-thick perfluoropolyethers (PFPEs)”, RSC Adv. (IF = 3.485), 2015, 5, 30570-30576

- Kozbial, A.; Li, Z.; Iasella, S.; Taylor, A.; Morganstein, B.; Wang, Y.; Sun, J.; Zhou, B.; Randall, N.; Liu, H.* and Li, L.* “Lubricating graphene with a nanometer-thick perfluoropolyether”, Thin Solid Films (IF = 1.790), 2013, 549, 299

- Li L.*; Wang Y.; Gallaschun C.; Risch T. and Sun J. “Why can a nanometer-thick polymer coated surface be more wettable to water than to oil?”, J. Mater. Chem. (IF = 6.626), 2012, 22(33), 16719-16722

- Wang Y.; Sun J. and Li L.* “What is the role of the interfacial interaction in the slow relaxation of nanometer-thick polymer melts on a solid surface?”, Langmuir (IF = 4.210), 2012, 28, 6151-6156

- Wang Y.; Williams K. and Li L.* “Understand the mechanism of anomalous viscosity-molecular weight relationships of diolic perfluoropoly (oxyethylene-ran-oxymethylene) ”, Macromol. Chem. Physic. (IF = 2.399), 2011, 212, 2685-2690

ON DEMAND TREATMENT OF WASTEWATER USING 3D-PRINTED MEMBRANE

Wastewater is a multicomponent and multiphase oil-water mixture. The state-of-the-art membrane is made of one material and has one pore size (with certain distribution). As a result, each membrane has only one “selectivity” and cannot separate the multicomponent and multiphase mixture in a single processing step. As a result, the liquid-liquid separation using a membrane usually involves multiple membranes and separation steps. Although membrane technology in general is more energy efficient compared to conventional separation methods, the multi-step processing increases the cost, energy and physical footprint. Moreover, in the current membrane fabrication process, the distribution of pore size and pore topography is wide, which negatively impacts the selectivity of the membrane. We are developing 3D-printed membrane with multiple selectivity for multicomponent and multiphase oil-water separation, which is critical to wastewater treatment in the chemical industry.

ACKNOWLEDGEMENT